Biosafety Cabinets: Types & Mechanism

Bioafety cabinets are used in the laboratory for procedures in which either the reactants are to be protected from contamination by the worker or environment you can learn here as the worker needs protection or safety during handling of infectious material or both of these are to be protected from each other. Based on the requirement, various types of biosafety cabinets are available.

1- LAMINAR FLOW CLEAN-AIR SAFETY CABINET:

In this type of cabinet, air is first purified from particulate matter including microorganisms, with the help of a blower by passage through a HEPA filter under pressure. This clean air then flows, in laminar fashion, through the cabinet and to outwards from the operating front. This protects the work being carried out in the cabinet from contamination with microorganisms but cannot protect worker from infectious material if handled inside the cabinet. Therefore, this type of cabinet is used for clean work, such as preparation of media, putting up tissue/cell cultures and handling sterile tissue. It is not suitable for handling infectious material.

2- CLASS-I MICROBIOLOGICAL BIOSAFETY CABINET

In this type of safety cabinet the air is drawn from outside into the cabinet from operating front and then it is passed through a HEPA filter and blown out with a blower fan. Air flows across the front panel or opening around worker into the cabinet. Therefore it protects the worker and the atmosphere from exposure or contamination from the material being handled in the cabinet. This is used to handle infectious material.

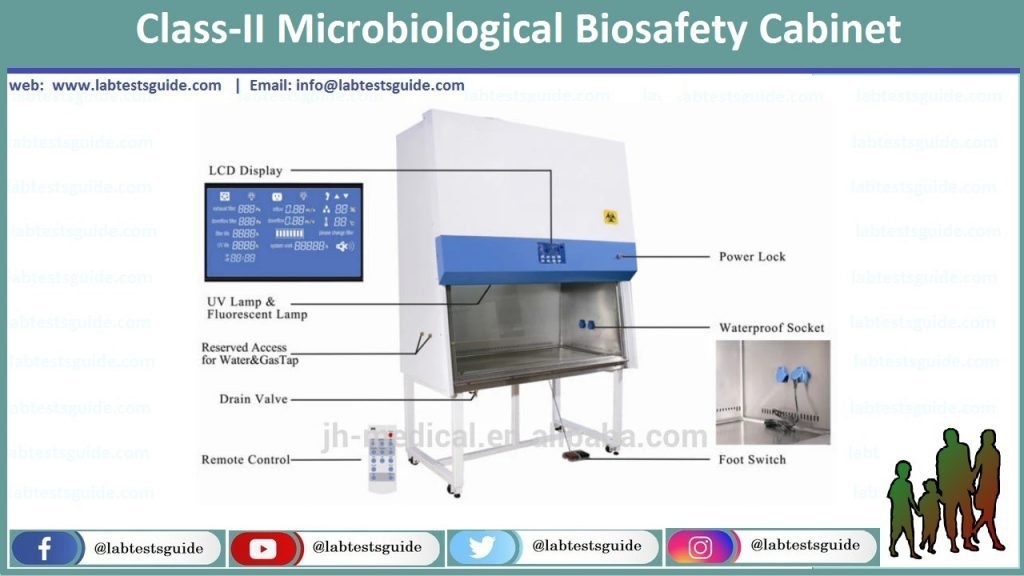

3- CLASS-II MICROBIOLOGICAL BIOSAFETY CABINET

In this type of cabinet air is blown into the cabinet from the top after purification by passing it through a HEPA filter. The purified air flows towards base of the cabinet from where it is blown out of the cabinets again after purification by another HEPA filter. The pressure of air inside the cabinet does not allow air from the atmosphere to enter the cabinet through the open operating front. This type of cabinet protects operator, material inside the cabinet and atmosphere. This is most commonly used safety cabinet in experimenting with contagious material.

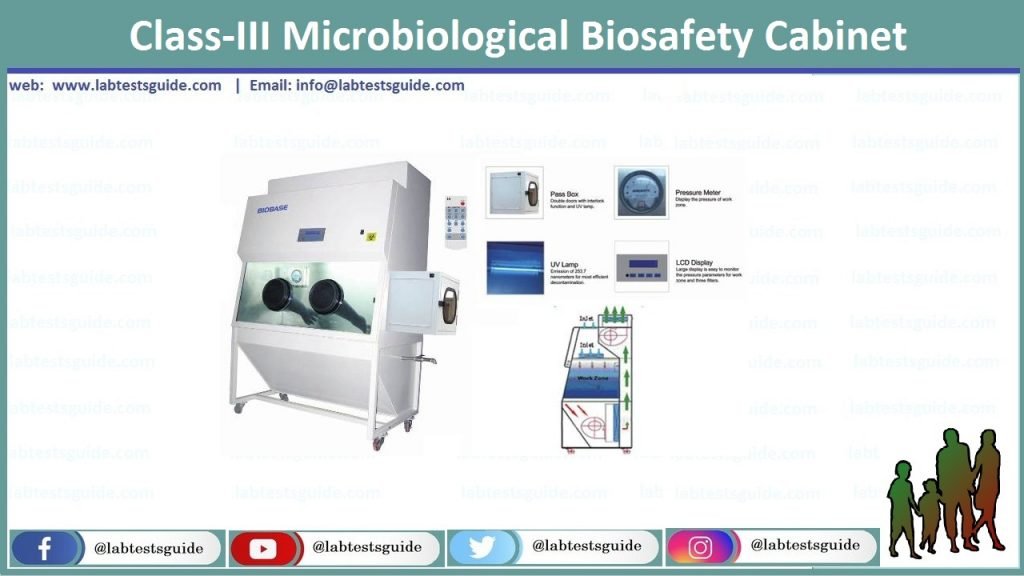

4- CLASS-III MICROBIOLOGICAL BIOSAFETY CABINET:

The basic design of this type of cabinet is the same as that of Class-II cabinet except that:

- Operating is front closed with a curtain which has in-built gloves to handle the material placed inside the cabinet.

- Multiple HEPA filters are provided both at the inflow and outflow of air.

- This cabinet provides maximal protection to the operator, material and the environment. This type of cabinet is used when highly infectious/contagious material is to be dealt with.

Most of the cabinets are provided with ultraviolet lamps inside the cabinet. These can be switched on for additional sterilization when required.

PRECAUTIONS AND MAINTENANCE

- All the material required for the experiment or procedure to be carried out should be placed inside the cabinet before starting the actual work.

- The cabinet shall then be switched on. If UV light is required it should also be switched on.

- The operator must wear all personal protective equipment even when using the safety cabinet.

- At the end of the work session, all articles should be removed from the cabinet. UV lamp and the fans should be switched off.

- The cabinet should then be thoroughly cleaned, first with suitable detergent and then with a disinfectant. It should be wiped dry and closed. Never leave the cabinet open without cleaning.

- Particular attention should be paid to the perforated base and the space underneath while cleaning.

- HEPA Filter must be replaced as advised by the manufacturer or whenever damaged or clogged.

- UV lamp, blowers etc. should be checked and serviced regularly.

Related Articles

RELATED POSTS

View all